Consultant

MB China racking system provides a full range of warehouse storage consulting services

There are so many warehousing equipment on the market, and buyers are in different industries. How to choose a warehousing solution that suits them best and help them achieve efficient use of effective space at the lowest cost is our goal.

Therefore, the company has a high-quality sales team and technical team responsible for the demand forecast of each project.

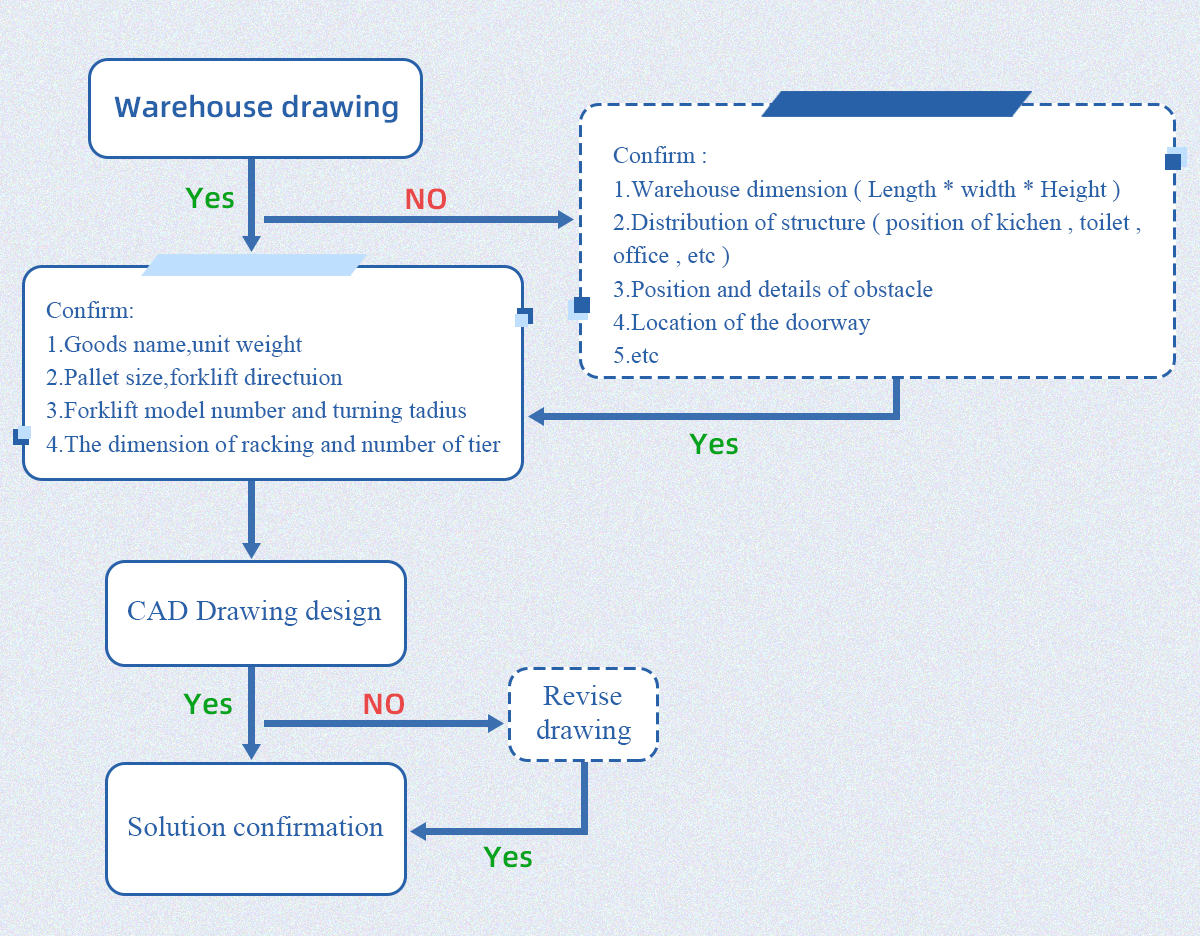

The MB sales team will first confirm the customer's storage needs, item information, and load requirements, and then determine the most suitable storage system for the customer's needs. Next, the engineers analyze all the environmental parameters, that is, the parameters related to the area where the shelves will be installed, such as the structure of the warehouse, the location of the fire passage, the condition of obstacles, and seismic activity and weather. Finally, where applicable, they integrate different systems into one system to ensure optimal performance.

Customized Solution

Rack Assembly

Steps to assemble the shelf:

1. Check the delivery note and the actual quantity delivered, and observe whether the accessories on the shelf are intact.

2. First look at the assembly drawings carefully, understand the general structure of the shelf, and sort out the installation sequence.

3. Begin to assemble the column first, and install the foot pads on the column first.

4. Then assemble the top and bottom triangles. Use the screws to install the triangles on the column, but don't tighten the screws too tight, just bring them on, so that you can adjust them after all assembly is completed.

5. Then assemble the top and bottom load-bearing plates, which can also be attached with screws, don’t tighten them too tightly.

6. Next, assemble the middle load-bearing plate and place it in the middle at an angle, and place it in a suitable position according to the design of the floor height. Then use the screws to bring the triangle, the load-bearing plate and the column together, or do not tighten the screws too tightly.

7. Finally, stand the shelf up and keep it vertical against the wall. Then tighten the screws gradually from the bottom up. After all the screws are tightened, you can shake the shelf with both hands to see if the shelf is stable. After the shelf is stable, the assembly is completed.

Precautions for assembling shelves:

1. Reserve an area for the shelves, try not to put the shelves outside in the sun or rain.

2. Keep the installation site tidy and clean up dust and garbage.

3. Level the ground before assembly to ensure the stability of the shelf installation. The smoother the ground, the better.

4. Pay attention to lifting and placing gently to avoid bending and deformation of the shelf or abrasion of the surface spray.

Rack Maintenance

The use of storage shelves is widely used in many companies now. Storage shelves are made of steel and most of them are disposable equipment. Many people only know how to increase the warehouse space and the convenience of storing goods by using shelves, but do not know how to maintain the shelves and extend its service life.

1. Anti-collision protection. Most of the most easily damaged racks are the aisles and the columns at the corners, which are usually deformed by the forklift. According to different shelves, channel widths and transportation tools, the shelf suppliers have matching anti-collision feet and anti-collision rail equipment. Crash barriers should be installed in the passage. The installation of anti-collision rails and anti-collision feet play a very important role in protecting the column.

2. Anti-stress. The shelves of different specifications are designed and manufactured according to the load-bearing design. Therefore, the weight of the goods placed on the shelf must be within the allowable range of the shelf load. It is best for the warehouse manager to mark the load-bearing limit on the shelf. Follow the principle of heavier on the bottom of the shelf, that is, put heavy objects on the bottom layer and light objects on the upper layer.

3. Moisture-proof, sun-proof and rain-proof. Although the columns, beams and laminates of the shelves are all metal products, and the surface is painted, but after being exposed to moisture and sun, they may rust over time and affect their service life. Even if the shelf layer is made of wood, the position near the window is most likely to receive rain, and the wood will deform and warp after rain.

4. Require special personnel to use push-up trucks. In particular, heavy-duty and high-rise warehouses must be equipped with powered push trucks, and the use and operation of push trucks must only be operated by qualified personnel. Most of the warehouse rack columns are deformed due to the use of pusher trucks by non-designated personnel. In addition, the shelf beams are best customized to be yellow for identification by the operator of the pusher.

5. Specify the standard pallet size and delivery size. Commonly used pallet size width is between 0.8-1.2 meters. For example, the beam of the heavy beam type rack is generally 2.5/2.7 meters, and is designed according to the width of two pallets on one layer. If the pallet used is non-standard. Or the size of the goods placed on it exceeds 1.2 meters, and it may hit the column when it is jammed or pulled on the shelf.

6. Prescribe shelf use system. Different warehouses and different shelves have different usage methods. The warehouse manager should formulate a shelf use system, so that every shelf user can learn and abide by it, in order to finally achieve the goal of protecting the shelf.